Composite Corded Strap: The Ultimate Solution for Heavy-Duty Packaging

In the world of packaging, finding a reliable and durable solution is crucial, especially when dealing with heavy loads or critical shipping requirements. Composite Corded Strap has emerged as a standout option for businesses looking to enhance their packaging efficiency and security. Made from advanced materials, this strap is designed to meet the rigorous demands of various industries.

What is Composite Corded Strap?

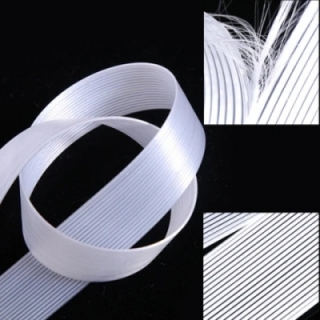

Composite Corded Strap is a high-strength bundling material that combines the flexibility of polypropylene with the added strength of cord reinforcement. This unique design offers superior tensile strength and durability, making it ideal for securing heavy loads during transport and storage. The strap is lightweight and easy to handle, ensuring a smooth packaging process without sacrificing performance.

Key Features of Composite Corded Strap

High Strength: The cord reinforcement provides remarkable strength that can withstand the rigors of shipping and storage, making it suitable for heavy-duty applications.

Flexibility and Ease of Use: Despite its high strength, the strap remains flexible and easy to handle. It can be adjusted and manipulated easily, ensuring a secure fit around your products.

Resistant to Environmental Conditions: Composite Corded Strap is designed to withstand various environmental factors, including moisture and UV exposure, ensuring that it maintains its integrity over time.

Cost-Effective Solution: Compared to traditional metal strapping, the Composite Corded Strap offers a more economical option without compromising on strength or quality. It significantly reduces the risk of damage to your products during transport.

Versatile Applications: This strap is suitable for a range of industries, including construction, agriculture, furniture, and logistics. Whether you are bundling heavy equipment or securing pallets of goods, Composite Corded Strap has you covered.

How to Use Composite Corded Strap

Step 1: Prepare Your Products

Ensure that the items you intend to bundle are neatly arranged and ready for strapping.

Step 2: Cut the Strap to Length

Measure the length of the Composite Corded Strap needed to securely wrap around your products. Cut the strap to the desired length, allowing extra for overlaps.

Step 3: Position the Strap

Wrap the strap around the items, ensuring it is positioned evenly and securely.

Step 4: Secure the Strap

Use appropriate tensioning tools or buckles to secure the strap in place. Ensure that it is tight enough to hold the items securely without causing damage.

Advantages of Using Composite Corded Strap

Improved Efficiency: The ease of handling and securing loads with Composite Corded Strap speeds up the packaging process, leading to increased productivity.

Safety: Reduces the risk of accidents and damage during transport, protecting both the products and the workers involved in the shipping process.

Environmentally Friendly: Many composite straps are recyclable, making them a more sustainable choice in packaging solutions.

Conclusion

Composite Corded Strap is a reliable, efficient, and cost-effective solution for all your heavy-duty packaging needs. With its excellent strength, flexibility, and resistance to environmental factors, it is the ideal choice for businesses looking to optimize their packaging processes.

If you’re interested in learning more about Composite Corded Strap or how it can benefit your operations, feel free to reach out to us! We’re here to help you find the right packaging solutions tailored to your needs.