Composite Corded Strap: The Ultimate Solution for Heavy-Duty Bundling

In an era where efficiency and sustainability are paramount, businesses across various industries seek reliable packaging materials that can withstand the demands of heavy-duty applications. Composite corded strap has emerged as a favored solution, combining strength, flexibility, and durability. This article explores the features, benefits, applications, and best practices associated with composite corded strap, highlighting why it has become an indispensable tool for companies dealing with bundling and securing loads.

What is Composite Corded Strap?

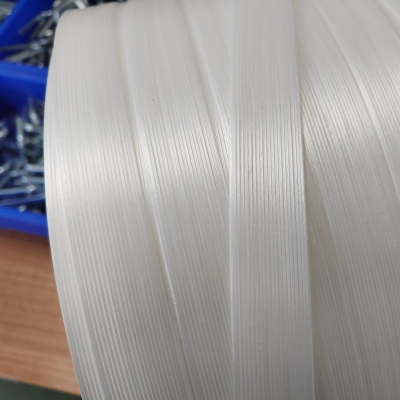

Composite corded strap is a packing material that integrates the best qualities of multiple materials, typically combining a core of high-strength polyester with a protective outer layer. This unique construction gives the strap excellent tensile strength and flexibility, enabling it to handle heavy loads without breaking or stretching. The corded design further enhances the strap's resistance to abrasion, UV light, and moisture, making it suitable for both indoor and outdoor applications.

Features and Benefits

1. Exceptional Strength and Durability

One of the standout features of composite corded strap is its remarkable strength. With a high tensile strength rating, this strap effectively secures even the heaviest bundles, which is critical in industries like construction, automotive, and manufacturing. Its durable construction allows it to maintain its integrity under pressure, reducing the risk of breakage during handling and transportation.

2. Lightweight and Flexible

Despite its strength, composite corded straps are lightweight and easy to handle. This characteristic allows for quick and efficient bundling, as workers can maneuver the strap without unnecessary strain. The flexibility of the strap also facilitates the secure wrapping of irregularly shaped loads, ensuring a snug fit that minimizes shifting during transit.

3. Weather and UV Resistant

Composite corded straps are designed to withstand various environmental conditions. The protective outer layer helps prevent degradation from exposure to UV rays, moisture, and extreme temperatures. This resistance ensures that the strap maintains its performance even in challenging outdoor situations, making it an ideal choice for shipping and storage in variable climates.

4. Cost-Effective Solution

When compared to traditional steel strapping or other heavy-duty materials, composite corded strap offers a cost-effective alternative. It provides similar strength and performance levels but at a lower overall cost, allowing businesses to reduce their packaging expenses without compromising on quality. Additionally, the lightweight nature of the strap can lead to lower shipping costs, further enhancing its economic benefits.

Applications of Composite Corded Strap

Composite corded strap is versatile and suitable for a wide range of applications, including:

Construction: Used to bundle and secure various materials such as wood, bricks, and metal components on job sites.

Manufacturing: Ideal for securing products during the production process and preparing them for transport.

Automotive: Commonly employed to bundle parts and components for delivery to manufacturing plants.

Shipping and Logistics: Essential for securing loads on pallets and containers, ensuring stability during transit.

Best Practices for Using Composite Corded Strap

To maximize the effectiveness of composite corded strap, consider the following best practices:

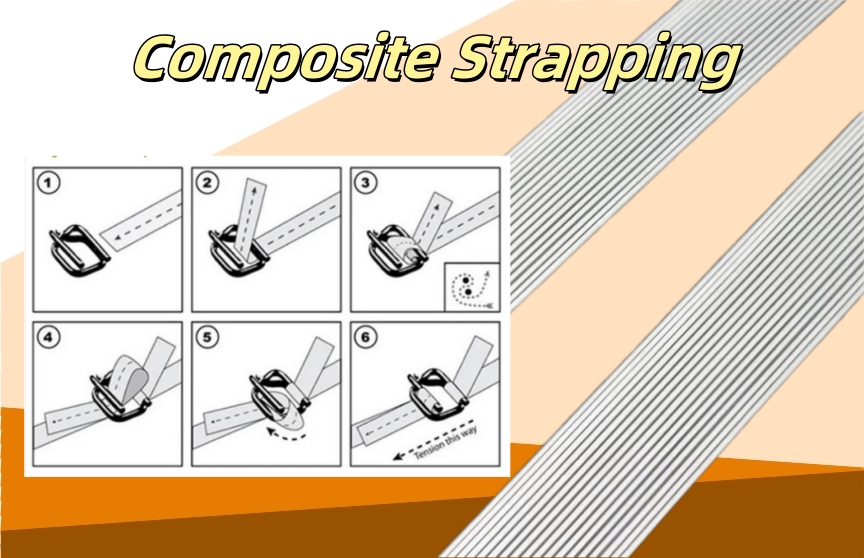

1. Proper Equipment

Use appropriate tools for tensioning and sealing the strap. Tensioners ensure a snug fit, while seals (such as buckles) secure the strap in place without risk of slippage.

2. Adjust Tension Levels

Adjust the tension of the composite corded strap according to the weight and shape of the load. An overly loose strap may lead to shifting, while too tight may cause damage to the products being secured.

3. Training Staff

Ensure that staff members are adequately trained in the proper use of composite corded strap and the associated equipment. This training can help prevent accidents and improve bundling efficiency.

4. Regular Inspections

Regularly inspect the strap for signs of wear or damage. Replace any damaged straps immediately to ensure continued performance and safety.

Conclusion

Composite corded strap has become the go-to solution for businesses seeking a robust, lightweight, and cost-effective bundling material. Its unique combination of strength, flexibility, and weather resistance makes it suitable for a multitude of applications across various industries. By utilizing composite corded strap effectively, companies can enhance their packaging processes, improve operational efficiency, and ensure the safe transport of their products. As the industrial landscape continues to evolve, adopting reliable materials like composite corded strap will be crucial for maintaining competitiveness and sustainability in an increasingly demanding market.