Composite Corded Strap: Enhancing Efficiency and Safety in Packaging

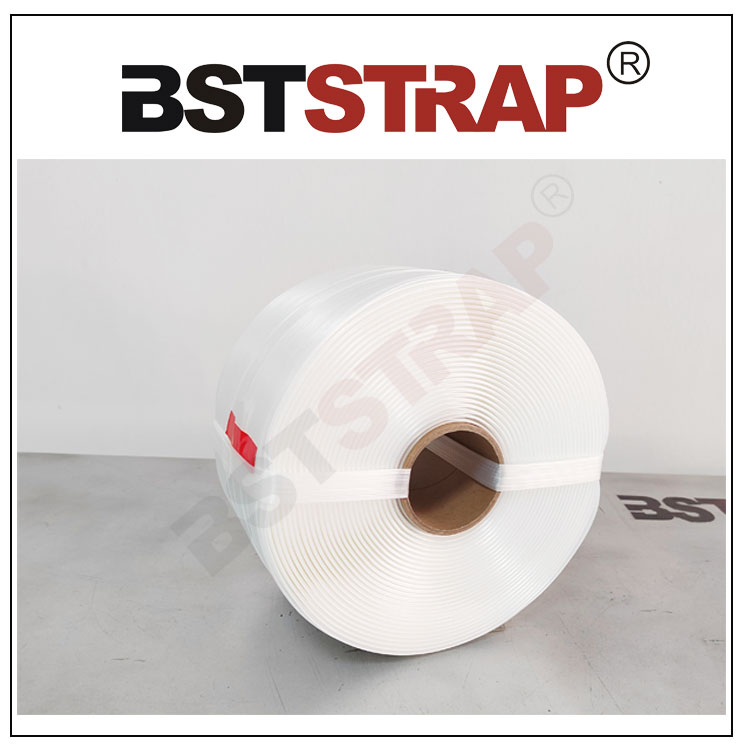

What is a Composite Corded Strap?

A Composite Corded Strap is a modern packaging material widely used for binding and protecting goods across various industries. It is made of high-strength synthetic fibers combined with other reinforcing materials, offering both flexibility and strength, making it a vital choice for safe transportation and storage.

Features of Composite Corded Straps

1. High Strength and Durability

Composite corded straps utilize high-performance synthetic materials, capable of withstanding significant tension and weight. Whether in heavy industries, logistics transportation, or construction sites, the tear and abrasion resistance of composite corded straps ensure that goods remain secure and undamaged.

2. Lightweight and Easy to Handle

Compared to traditional steel cables or other binding materials, composite corded straps are significantly lighter and easier to operate. This lightweight design allows users to bind and unbind goods with ease, reducing labor costs and saving time.

3. Corrosion and Water Resistance

The materials used in composite corded straps possess excellent corrosion and water resistance, making them suitable for various harsh environments. This ensures that they maintain good performance in outdoor and damp working conditions, reducing damage caused by environmental factors.

4. Eco-Friendly Materials

As environmental awareness increases, the production materials for composite corded straps comply with sustainable development requirements. Many manufacturers use recyclable materials to produce composite corded straps, minimizing the environmental impact and making them suitable for various businesses.

Application Areas

Composite corded straps have a wide range of applications across several industries, including but not limited to:

Logistics and Transportation: Effectively binding goods, reducing movement and damage during transportation.

Construction: Used to support and transport heavy objects, ensuring safety during construction processes.

Agriculture: Serving as binding materials for crops, tools, and equipment in agricultural production.

Manufacturing: Protecting and stabilizing products during final packaging before leaving the factory.

Reasons to Choose Composite Corded Straps

1. Cost-Effectiveness

The durability and efficiency of composite corded straps provide significant cost benefits over time. While the initial investment may be higher than other materials, their longevity and reduced damage rates significantly lower overall maintenance and replacement costs.

2. Safety

Using composite corded straps effectively reduces safety hazards associated with improper binding. Their powerful load-bearing capacity and good stability ensure that goods remain safe during shipping and storage, decreasing the likelihood of accidents.

3. Flexibility and Versatility

Composite corded straps can be customized based on different customer needs, demonstrating remarkable flexibility. Whether in size, color, or tensile strength, they can be designed to meet various scenarios, catering to diverse client requirements.

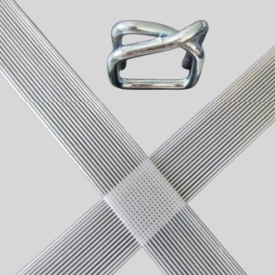

How to Use Composite Corded Straps Correctly?

When using composite corded straps, there are a few key points to consider:

Inspect Strap Integrity: Before each use, check the strap for wear or damage to ensure its safety performance.

Proper Binding: Follow basic binding principles to ensure that the strap is tight without being overly stretched.

Storage Method: Avoid storing in damp or direct sunlight environments; keeping the strap dry and clean will extend its lifespan.

Conclusion

As an efficient binding material, composite corded straps have become indispensable packaging tools across industries due to their exceptional performance and eco-friendly features. By selecting the right composite corded strap, you can enhance operational efficiency and effectively ensure the safety of your goods. Let’s move toward a more efficient and safe future in the packaging sector!