Composite Cord Strapping: A High-Strength, Versatile Packaging Solution

In modern logistics and industrial sectors, safely and efficiently securing and transporting goods is crucial. Composite Cord Strapping, as an innovative packaging material, is increasingly becoming the preferred choice for numerous industries. It not only possesses excellent strength and durability but also offers lightness, flexibility, and ease of handling, providing an ideal solution for various packaging needs.

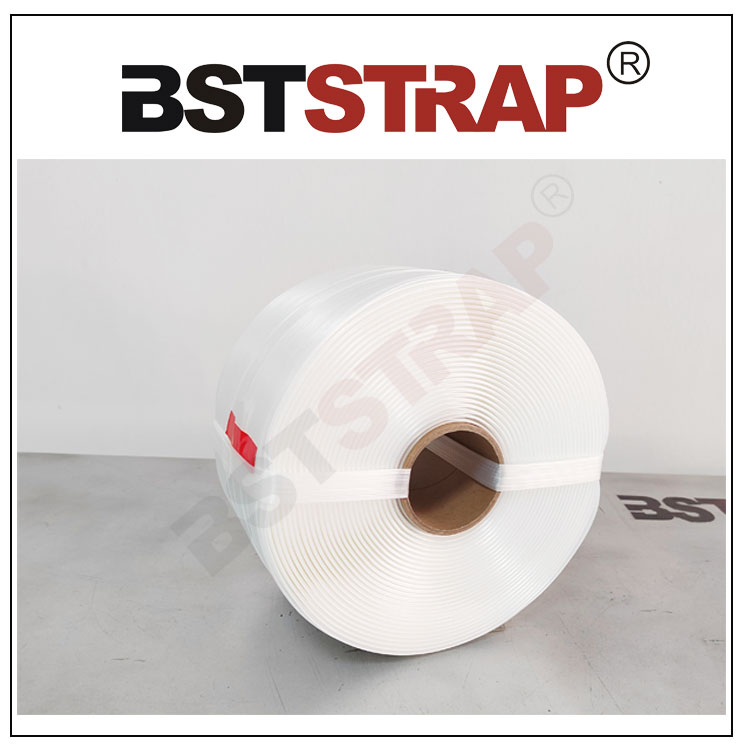

Composite Cord Strapping is primarily made of high-strength polyester or other synthetic fibers, which undergo special weaving or compositing processes to impart superior load-bearing capacity and abrasion resistance. Compared to traditional steel strapping or plastic strapping, Composite Cord Strapping is significantly lighter, weighing only about a quarter of steel strapping, making it more economically efficient during transportation and storage. Additionally, Composite Cord Strapping avoids the rusting issues associated with steel strapping, ensuring no damage to packaged items.

The application scope of Composite Cord Strapping is extremely broad. It is used in wood processing plants, railway freight, industrial automation, and many other fields to secure heavy goods, bundled items, and irregularly shaped objects. Its tightly woven structure and strong tensile strength keep goods stable during transportation, effectively preventing shifting and collisions. Furthermore, Composite Cord Strapping exhibits excellent weather adaptability, maintaining stable performance under various extreme climatic conditions to ensure the safety of goods.

To meet the needs of different customers, Composite Cord Strapping comes in various specifications and styles. From width, thickness, to length, it can be customized according to specific application scenarios. For instance, for heavy goods requiring high-tension fixation, Composite Cord Strapping with a wider width and stronger tensile strength can be selected; whereas for scenarios requiring lightweight and flexible operation, a narrower width and softer texture may be more suitable. Additionally, Composite Cord Strapping can be paired with various fasteners and tools, such as buckles, locks, and tensioners, further enhancing its convenience and efficiency in application.

In terms of environmental protection and sustainability, Composite Cord Strapping also demonstrates unique advantages. Its recyclable materials reduce the burden on the environment. Meanwhile, advanced production processes and technologies are employed in the production of Composite Cord Strapping, ensuring efficient material utilization and minimizing waste.

Composite Cord Strapping not only boasts outstanding physical properties and application advantages but also brings significant economic benefits. Its lightweight nature lowers transportation costs, while its durability extends service life, reducing replacement frequency. Additionally, the ease of operation and flexibility of Composite Cord Strapping improve work efficiency and reduce labor costs.

In summary, Composite Cord Strapping, as a high-performance packaging material, is playing an increasingly important role in the logistics and industrial sectors with its unique advantages. Whether for securing heavy goods, protecting valuable items, or improving transportation efficiency, Composite Cord Strapping can provide satisfactory solutions. In the future, with continuous technological advancements and expanding application fields, Composite Cord Strapping will usher in even broader development prospects.